[Asia Fluid Network News] Selection of deep well pump requirements: First, according to the caliper, the initial water quality pump. Different types of pumps have certain requirements on the hole diameter. The maximum size of the pump is less than 25 ~ 50mm of the hole diameter. If the borehole skew, the maximum size of the pump should be smaller. In short, the part of the pump body can not close to the inner wall of the well to prevent the pump from damaging the well due to vibrations of the pump. Second, according to the well water, selected deep well pump flow. Each well has an economically optimal volume of water that should flow at a rate equal to or less than the level at which the well water level drops to half the well depth. When the pumping capacity is greater than the machine water, it will cause the machine wall collapse and siltation, affecting the life of the well; if the pumping is too small, the benefits of the well can not be fully realized. So, the best way is to pump wells pumping test, with the wells may provide the largest amount of water for the selected well pump flow basis. Pump flow to the label number or label on the manual shall prevail. Third, according to the well water level decline and the water pipeline head loss. Determine the actually required head of the deep well pump, which is the head of the deep well pump, which equals the vertical distance (net head) from the water level to the surface of the sump with the loss lift. Lost head lift is usually 6 ~ 9% of the net head, usually 1 ~ 2m. Pump the lowest impeller into the water depth of 1 ~ 1.5m appropriate. The total length of the downhole portion of the pump tube shall not exceed the maximum length of the well into which it is specified in the pump instructions. Fourth, wells containing more than one ten thousandth of sediment wells, should not install the use of deep well pump. Because well water content is too large, such as more than 0.1%, will accelerate the wear of rubber bearings, causing pump vibration, shorten the pump life.

Material: SS304, SS316

Weave type: Plain weave, Twilled weave, Dutch weave

Features: Corrosion-resisting, Wear-resisting

Uses:Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, enviroment protection,

mine, airspace, paper-making, electronic, metallurgy etc.

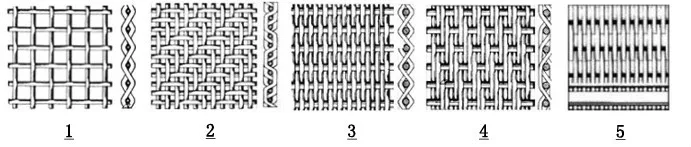

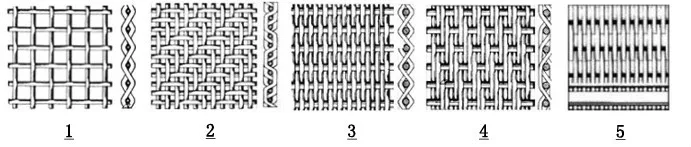

Weave type explanation

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves.

In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread

crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under

the warp threads that its neighbor went over, and vice versa.

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces

to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of

a yarn that crosses over two or more yarns from the opposite direction.

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires

Stainless Steel Series

Stainless Steel Series,Stainless Steel Wire Mesh,Stainless Steel Crimped Wire Mesh,Stainless Steel Window Screen

Anping Shengjia Hardware Mesh Co.,LTD , https://www.oilshaleshakerscreen.com

没有评论:

发表评论